News classification

Contact us

- Add: china-hena-hebi

- Tel: 13333923694(微信号)

- Fax: 13333923694

- Email: 908462358@qq.com

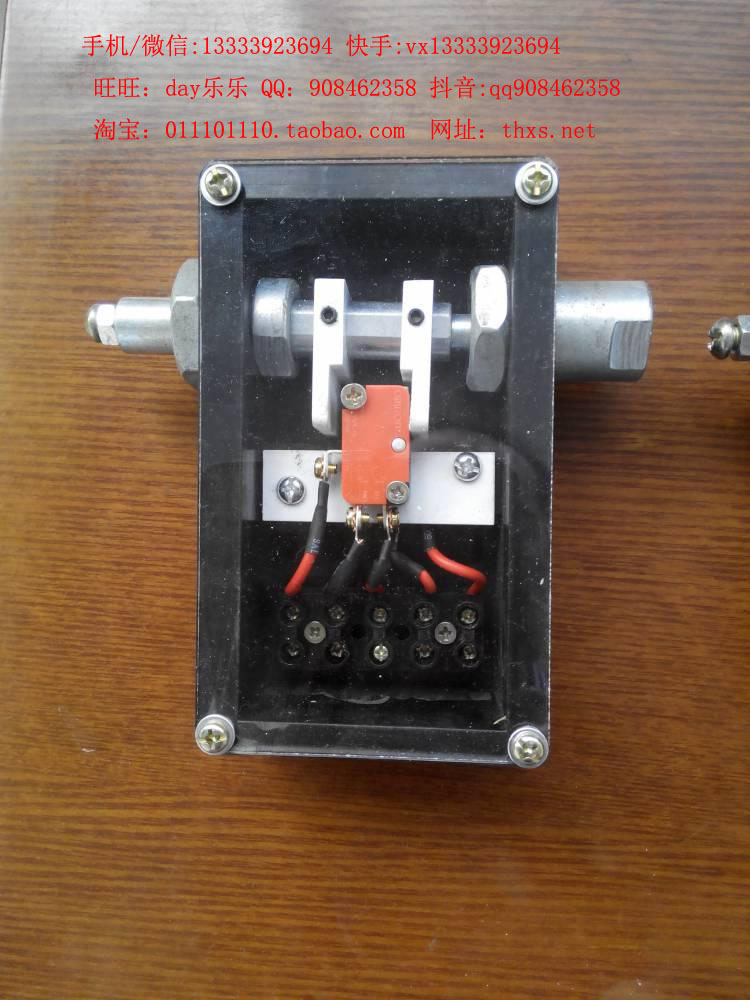

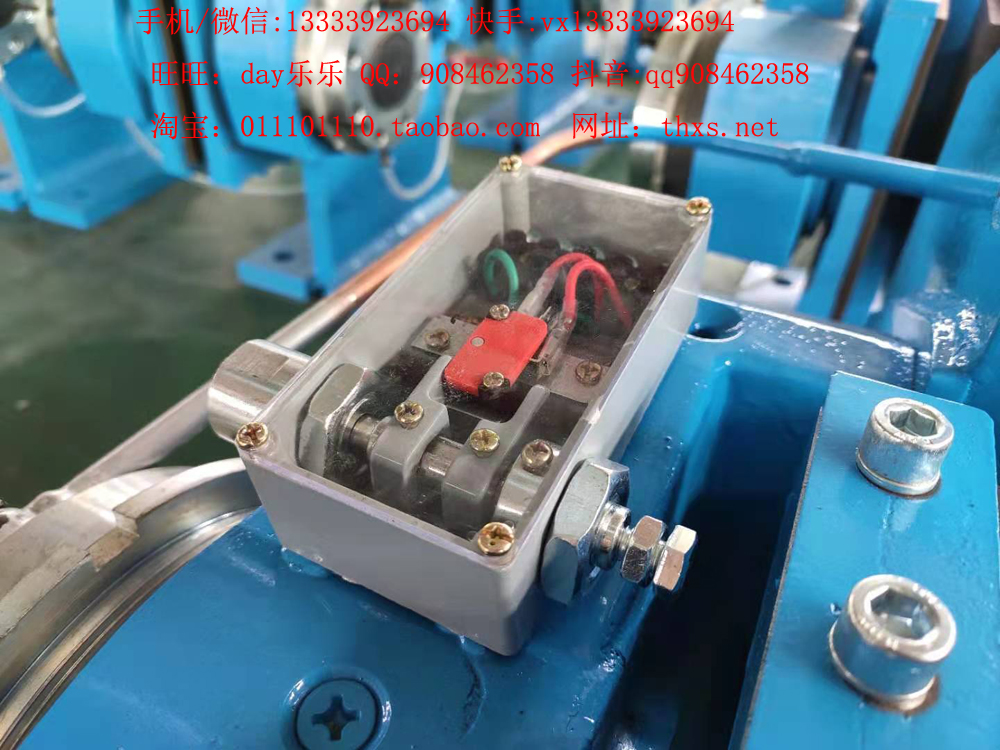

The following is an explanation of the adjustment settings between the brake shoes of the getTS249 032 type brake shoe wear switch and the brake shoe clearance adjustment for different models of mining brake shoes with lifting mechanism actuators:

In the brake system of the hoist, it is crucial to adjust the wear and clearance of mining brake shoes such as TS249, TS032, PS249B, JS-HH, etc. Firstly, increase the hydraulic station oil pressure to the opening oil pressure. Next, adjust the gap between the brake shoes to a range of 1 to 1.5 millimeters. Then, adjust the 1 adjusting screw on the diagram to make the contact push rod of the travel switch push against the baffle, and continue to adjust until the switch makes a "tick" sound. At this point, the normally closed contact is in the open state, and this switch state needs to be fixed. The use of normally closed contacts can effectively control the clearance between brake shoes.

When the sum of brake shoe wear and initial brake shoe clearance reaches 2.2 millimeters, the switch state will change. The normally closed contact that was originally disconnected is closed again, and the closed state can be used to send a signal to the alarm device, thereby triggering the alarm. By adjusting the settings in this way, the wear of the brake shoes can be monitored in a timely manner to ensure the safe operation of the hoist# Elevator # # winch # # brake shoe wear switch#