Product categories

News center

- Basic indicators of coal quality

- TS249 032 type brake shoe wear s

- Oxygenation gauge - pressure red

- JZ drilling winch assists in dee

- How to replace the oxygen bomb s

- calorimeter oxygen bomb leakage

- Aerobic fermentation of pig manu

- Organic fertilizer processing pl

- Technical Plan II for Upgrading

- Technical Plan for Upgrading and

- JK-3.5 Upgrade Winch by Adding B

- Safety Mark Certificate for Mini

- Commitment for Mine Winches and

- Safety Qualification Certificate

- Intelligent sealed high-temperat

- Certified by ISO9001:2015 Qualit

Contact us

- Add: china-hena-hebi

- Tel: 13333923694(微信号)

- Fax: 13333923694

- Email: 908462358@qq.com

Product Numbers:20231214142840

Price:0

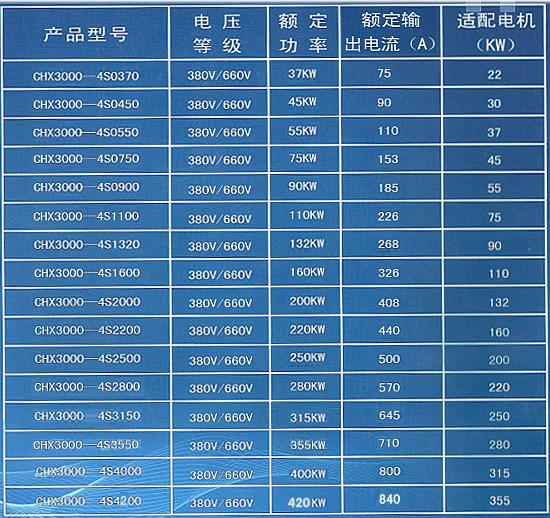

Product introduction:Frequency converter | Control instrument | Motor control instrument | Motor frequency converter | Frequency converter controls motor | Frequency converter servo motor | Single phase motor frequency converter | Fully automatic moto

| Upgrade the fully automatic motor digital controll | |

|

The fully automatic motor digital controller is based on the original frequency converter and has been developed by dozens of experts and scholars through years of continuous introduction and absorption of advanced foreign technologies. In May 2008, it was approved by the National Patent Office as a national patent product. Its excellent soft start performance, tracking energy-saving performance, frequency conversion speed regulation function, PLG programming control function, comprehensive protection function, and power braking function have reached the world's advanced level.。

BP-JTP110-P

This console is a frequency conversion console specifically designed for mining winches, with an internal PLC touch screen. It has the characteristics of simple and convenient operation, high safety factor, and so on.

The soft start function includes controlling the starting current within the rated current and ensuring high torque output (heavy load start) of the motor, meeting the starting needs of the motor under various industrial and mining conditions. The starting time can be set arbitrarily from 1 to 6000 seconds, and the entire starting process is stable, safe, and quiet, completely eliminating the impact of current on the power grid, motor, and equipment. Compared with the old-fashioned winch step-down start, it completely eliminates the impact on the steel wire rope

Continuously variable speed function: Based on the current motor control theory, a computer is used to construct a motor CNC platform. The new power semiconductor drive technology is used to achieve high-precision control of the motor in full digital mode, allowing for arbitrary speed regulation within the rated speed range of the motor, truly realizing the infinitely variable speed of the electric motor

Efficient and energy-saving function: Equipped with a dynamic vector automatic tracking and matching system, it can quickly adjust the input voltage of the motor according to the load changes of the motor, forcibly reduce the motor current, and ensure the efficient operation of the motor. Tested by national authoritative departments; No load power saving rate of 65%, average power saving rate of 45%

Comprehensive protection parameter memory function: equipped with dozens of comprehensive protection functions such as undervoltage, overvoltage, overcurrent, overheating, overload, overspeed, phase loss, and up and down over winding, allowing for easy access to operation records and fault history memory, facilitating fault monitoring and diagnosis.

Our company can provide customers with on-site variable frequency winch renovation according to their needs, and tailor the most practical variable frequency engineering for customers.

内部

1、 CNC soft start Control the starting current within the rated current and ensure high torque output (heavy load starting) of the motor to meet the starting needs of the motor under various working conditions. The startup time can be set arbitrarily from 1 to 6000 seconds, and the entire startup process is smooth, safe, and quiet, completely eliminating the impact of current on the power grid, motor, and equipment. 2、 Infinitely variable speed Based on modern motor control theory, a motor numerical control platform is constructed through computer technology, and a new type of power semiconductor drive technology is used to achieve full digital high-precision control of the motor. The motor can be adjusted arbitrarily within the rated speed, truly achieving stepless speed change of the motor. 3、 Efficient and energy-saving Equipped with a dynamic vector automatic tracking and matching system, it can quickly adjust the input voltage of the motor according to the load changes of the motor, forcibly reduce the motor current, and ensure efficient operation of the motor. According to testing by national authoritative departments, the no-load power saving rate is 65%, with an average power saving rate of 45%. 4、 Comprehensive protection parameter memory Equipped with dozens of comprehensive protection functions such as under voltage, over voltage, over current, overheating, overload, over speed, phase loss, and up and down over winding, it is easy to access operation records and fault history memory for fault monitoring and diagnosis. 5、 Energy feedback According to user needs, an energy feedback unit is set up, and the electrical energy generated by the inertial force during equipment operation is filtered and fed back to the power grid. 6、 PLC programming control Add LCD display screen and PLC programming control function according to user needs, with multi speed programming control, allowing for free setting and monitoring of equipment operation time, direction and position. 7、 Equipment concentration Due to the use of high-tech semiconductor control technology, the size and weight of the equipment have been significantly reduced. More flexible operation. Abandoning the drawbacks of traditional equipment such as bulkiness, difficulty in operation, and high noise. 8、 Easy to operate Installation and operation are extremely convenient, and with a little electrical knowledge, one can learn to install and operate equipment in just a few minutes. 9、 Widely applicable Suitable for energy-saving in mining lifting, fans, air compressors, and water pumps. It can also be used for speed matching and programmable energy-saving transformation in industries such as metallurgy, petroleum, chemical, cement, textile, papermaking, printing and dyeing. ◆ Adopting a Japanese imported CPU digital signal processor. ◆ Adopting the latest intelligent power module from Japan's wellhead. ◆ Full digital line voltage sine wave PWM control. ◆ High torque and high torque can be adjusted arbitrarily. ◆ Equipped with perfect PID adjustment and automatic closed-loop control. ◆ Built in and external braking units can achieve high-precision and high sensitivity power braking. ◆ Wide voltage design, able to meet harsh situations with large voltage fluctuations in the power grid. The carrier frequency can reach up to 13KHZ, achieving ultra quiet operation. Multiple control methods are available to meet the requirements of industrial field control. ◆ Password protection function.

|

frequency converter | Control instrument | Motor control instrument | Motor frequency converter | Frequency converter controls motor | Frequency converter servo motor | Single phase motor frequency converter | Fully automatic motor digital control instrument product