Product categories

News center

- Basic indicators of coal quality

- TS249 032 type brake shoe wear s

- Oxygenation gauge - pressure red

- JZ drilling winch assists in dee

- How to replace the oxygen bomb s

- calorimeter oxygen bomb leakage

- Aerobic fermentation of pig manu

- Organic fertilizer processing pl

- Technical Plan II for Upgrading

- Technical Plan for Upgrading and

- JK-3.5 Upgrade Winch by Adding B

- Safety Mark Certificate for Mini

- Commitment for Mine Winches and

- Safety Qualification Certificate

- Intelligent sealed high-temperat

- Certified by ISO9001:2015 Qualit

Contact us

- Add: china-hena-hebi

- Tel: 13333923694(微信号)

- Fax: 13333923694

- Email: 908462358@qq.com

Product Numbers:2024915152949

Price:0

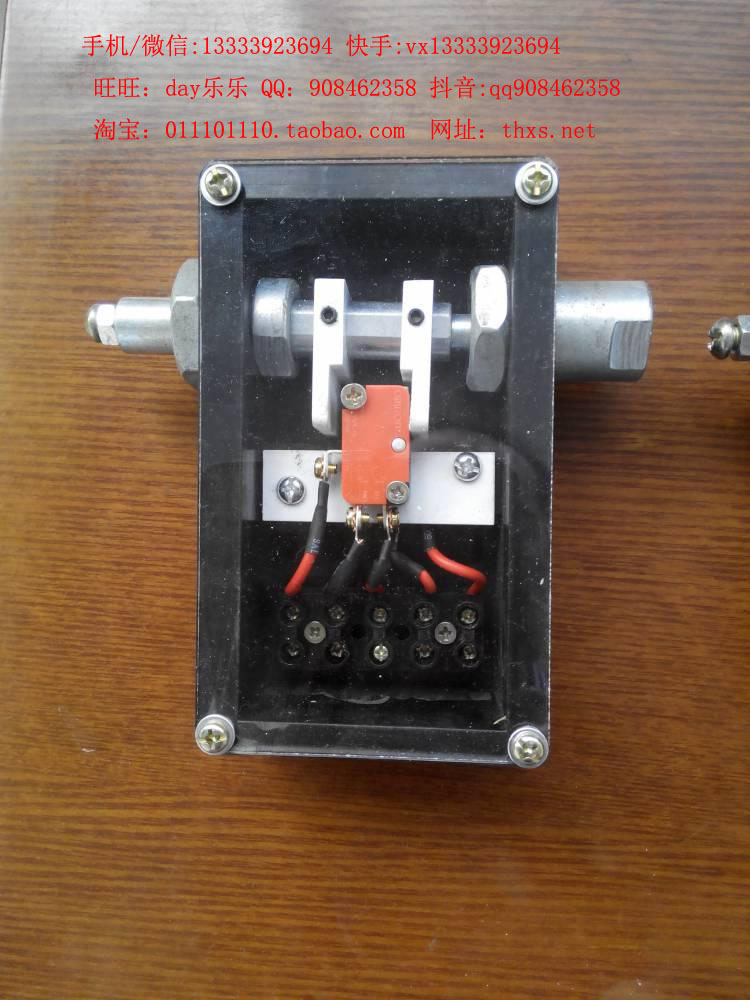

Product introduction:PS249B Brake Shoe Wear Switch, Disc Spring Fatigue Detection Switch

Brake shoe wear switch

Model: TS249, PS249B

Material: Aluminum, resin;

Voltage: 220V Current: 5A;

Keywords: Mine hoist disc brake shoe wear switch, brake shoe wear switch, coal mine hoist accessories - brake shoe wear switch, spring fatigue detection switch, disc brake gap detection/protection switch, mine hoist brake shoe gap protection brake shoe wear switch, brake shoe gap protection switch, hoist winch brake shoe wear switch;

Price of brake shoe wear switch and disc spring fatigue detection switch

Product detailed description

Our company produces a low potential contact pin type brake shoe wear switch. This utility model provides a low potential contact pin type brake shoe wear switch device, which consists of a contact pin electrode, an intermediate relay, a rectifier bridge, a control transformer, a time relay, an indicator light, and a buzzer. The output current of the control transformer is rectified by the rectifier bridge and output as direct current. The negative pole of the direct current is grounded, and the positive pole is connected to the contact pin electrode. There is a gap between the contact pin electrode and the brake disc. The alarm relay controls the opening and closing of the time relay and the sound and light alarm circuit. The indicator light and buzzer are connected in parallel, which is reliable and safe, and can reduce the point of electric shock and personal injury.

The brake shoe wear switch is designed specifically for detecting and controlling the brake shoe clearance of the hoist disc brake. It is a mechanical switch with dry contact output form, which can complete the detection of brake shoe clearance (using normally closed contacts) and the monitoring of disc spring fatigue damage (using normally open contacts). After being applied to the disc-shaped brake of the elevator, it can be directly connected to the "brake shoe wear alarm device" for monitoring, and can automatically sound and light alarms in case of safety issues; In addition, it can also be connected to the electronic control system, which can automatically shut down the power in case of safety issues. This setting can meet the requirements of the "Coal Mine Safety Regulations" regarding the control of brake shoe clearance

Price of brake shoe wear switch and disc spring fatigue detection switch

Adjustment setting of brake shoe clearance:

After the oil pressure of the hydraulic station is raised to the opening oil pressure, adjust the brake shoe clearance to 1~1.5mm, and then adjust the adjusting screw 1 as shown in the figure, so that the contact push rod of the travel switch is pushed onto the baffle plate and stops when the switch beeps. At this time, the normally closed contact is disconnected, and the switch status is fixed. The normally closed contact is used to control the brake shoe clearance. When the wear of the brake shoes plus the initial clearance of the brake shoes reaches 2.2mm, the switch state changes, that is, the normally closed state of the travel switch that has been disconnected is closed again, and the closed state is used to send a signal to the alarm device for alarm.