Special ignition wire for oxygen bomb calorimeter

Calorimeter in the detection of coal heating value, in full of oxygen in the oxygen bomb, add to the detection of the coal sample, installed ignition device (in the oxygen bomb), put an ignition wire, and then sealed lit. After calorimeter will automatically read out calorific value.

Material: high quality nickel wire;

In diameter, 0.1, 0.12, 0.15, 0.18, 0.20, 0.3mm;

Calorific value: 25J/10CM, 42J/10CM, 50J/10CM, etc.

Usage: it is used in coal laboratory instrument calorimeter, 0.3mm for ignition wire burned cotton ignition; below 0.2 for ignition wire direct ignition and ignition wire burned cotton ignition.

Method for correct use of ignition wire:

Good ignition wire, in the air through the test. Ignition on the cotton thread, the voltage regulation make ignition wire to dark red in the 4s-5s in fuse ignition, voltage regulation make ignition wire in the 1s-2s achieve a bright red;. Voltage, current, and power time should be measured accurately, so that the heat generated by the electric energy can be calculated. Such as the use of cotton ignition, in covering fire cover more than two electrode room for connecting a direct about 0.3mm bromide chromium wire, wire in the middle of the pre firing spiral laps to fever.

Note: 1 ignition voltage should be determined in advance, the ignition wire can be used to determine the heat of the metal wire, as long as the ignition is successful and to ensure the safety of the test time.

2 in the regulation of the amount of thermal instrument ignition current, the first ignition wire plug in the oxygen bomb on the two electrode, and then manually ignition. In the middle of the air, the red is red, and the current size is appropriate. Such as the ignition wire burning in the air, the amount of heat meter current is too large. Such as the ignition wire in the air is not red, the amount of heat meter current is too small.

Failure analysis and processing method of ignition failure:

If the ignition wire has been broken, and the reasons are not sample burning:

1 the ignition wire is too far from the sample.

2 insufficient oxygen or oxygen bomb.

Such as the ignition wire is not burned, can be a wire bundle on two ignition electrodes, running the ignition test function, to see if the fire wire is burned, such as the ignition wire burning, ignition failure reason for the ignition electrode and oxygen bomb contact problem or oxygen bomb itself:

1 ignition electrode rod port or oxygen bomb cover the surface oxide layer, to be polished with sandpaper.

2 on the ignition electrode is not enough to contact the spring, so that it can not contact the oxygen bomb cover, replace the spring.

3 oxygen bomb inside the insulation board and the ignition electrode short circuit, it is required to re adjust its position.

The 4 bomb inside the ignition wire fixing nut port of an oxide layer, to be polished with sandpaper.

Such as the ignition wire is not burned, the ignition failure of the reasons:

1 ignition power line or line.

2 ignition circuit damage.

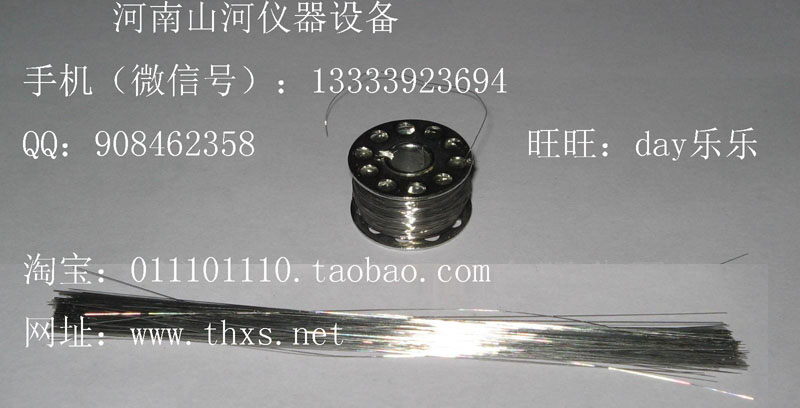

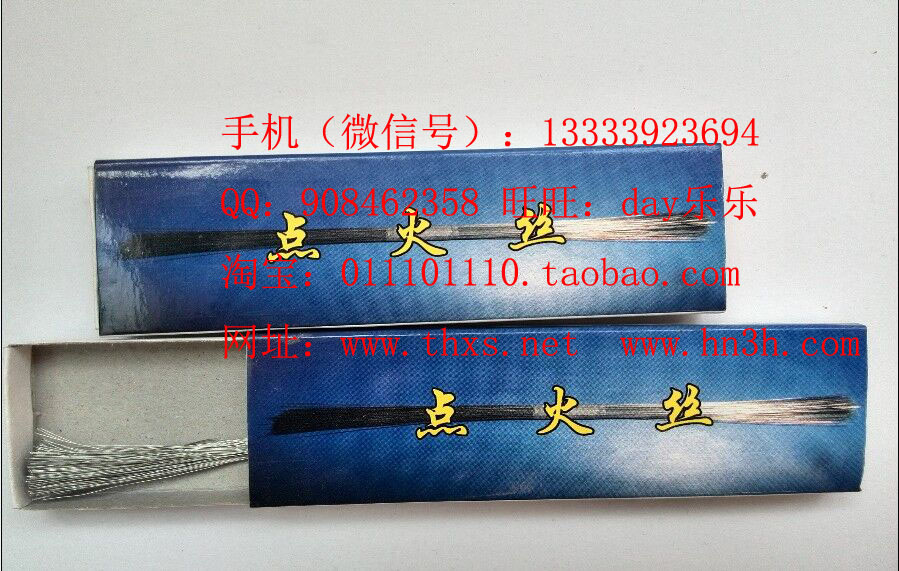

Calorimeter supplies: ignition wire roll and two kinds of packaging box;

|

|

|

|

|

Roll type ignition wire (sewing machine whistle volume)

Specification: Phi 0.12, Phi 0.2, Phi 0.3;

Length: 60 m;

Note: below 0.2 for ignition wire direct ignition and ignition wire

burned cotton ignition; 0.3mm for ignition wire burned cotton ignition.

|

|

|

|

Cassette ignition wire

Specifications: diameter of 0.12*100 and 0.10*100;

Light heating value: 50J;

Burning part of the calorific value: 25J;

Number: 1000PCS, 500PCS and 300PSC three, of which 300 is the root of iron box, diameter: 0.2.

|

|